Waterproof is a systematic work. It is only a material with high performance index, which cannot solve the waterproof problem. Jinlong Company has developed NDF waterproof system for various underground works (basement bottom plate, side wall, subway, etc.) in accordance with the current situation and requirements of waterproof.

NDF waterproof system adopts the combination of reactor technology and creep technology to develop the tightest waterproof system without leakage.

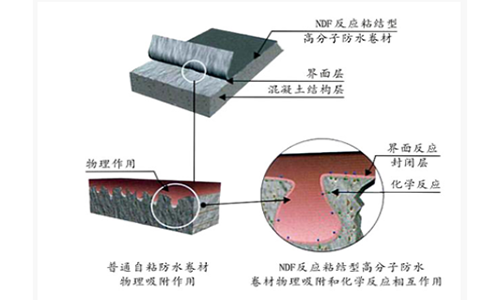

The reactive adhesion technology is one of the most advanced waterproof technologies in the world. This technology fully solves the compound problem of the waterproof layer and the base layer, to form a waterproof body which is integrated into a whole, so that after the partial damage occurs, a channeling water belt cannot be formed between the waterproof layer and the base layer, so that the leakage rate is reduced, and the maintenance easiness is improved.

Jinlong Company conducts further research and development on this technology. By adopting the modifier independently researched and developed by the Company, the reaction adhesive layer produced by our Company can better react with the base layer to form an adhesive connection which is fully combined with the main body to penetrate. Moreover, the reaction adhesive layer has creep property. When a sharp object damages the waterproof layer, the reaction adhesive layer can be automatically repaired, without water leakage.

NDF reaction adhesive waterproof coiled material is the most advanced waterproof product developed by our Company on the reaction adhesive technology. This product has very high adaptability. It has quite excellent performance in terms of tensile force, elongation, waterproof property and bonding of base layer and main body. After construction, it will form a waterproof system with permanent water channeling and self-healing capacity. It well solves the persistent problem of underground engineering leakage in the waterproof industry.

NDF reaction adhesive series waterproof coiled materials are divided into three categories:

NDF EVA reaction adhesive waterproof coiled material

NDF EVA reaction adhesive waterproof coiled material is a kind of high molecular self-adhesive waterproof coiled material made of EVA homogeneous sheet as main waterproof layer, the upper or lower surface of which is coated with a layer of rubber asphalt self-adhesive material with creep function and then coated with silicon oil anti-adhesive isolation film.

When the NDF EVA is bonded with the waterproof roll on the concrete structure layer, the skin is transplanted to the body to form a tight-closed, high-ductility, thin and functional protective layer.

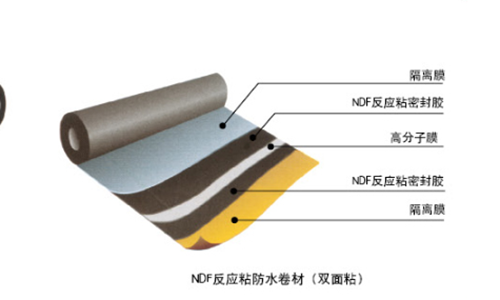

NDF high-polymer self-adhesive film/cross laminated film series waterproof coiled material

Jinlong Company continues to use the idea of “skin-type” waterproof, aiming at the special waterproof requirements of the basement floor and the basement side wall with external and internal protection on the basis of the original self-adhesive coiled material, and develops the pre-applied reverse-adhesive high-polymer self-adhesive waterproof coiled material--high-polymer self-adhesive film/cross laminated film waterproof coiled material suitable for the above-mentioned parts.

The high-polymer self-adhesive film/cross laminated film waterproof coiled material consists of a high-polymer sheet material, a self-adhesive rubber asphalt sizing material and an isolating film. This coiled material integrates with the advantages of polymer waterproofing film and self-adhesive waterproof coiled material, with highly properties such as puncture resistance, weathering resistance, high and low temperature resistance, and self-healing. And it can be bonded with post-pouring concrete to make coiled material bonded with the concrete into a whole. No danger of water channeling.

Since the coiled material is firmly adhered to the concrete of the bottom slab, the defects of the structure are basically covered by the layer of flexible “skin”, and the damaged part of the “skin” is basically blocked by the concrete of the base plate. It can be seen that: Imperfect coiled material waterproof layer and the same imperfect structure are barriers to each other, forming a nearly perfect defense system.

Schematic Diagram of Structure

|