Product Overview

The self-adhesive polymer modified asphalt waterproof coiled material (hereinafter referred to as Class N) is made of synthetic rubber such as SBS, high-quality road asphalt and tackifier as base material, polyester film (PET), polyethylene film (PE), aluminum foil or silicone-coated isolation film as upper surface material, and the lower surface is coated with a silicone-coated isolation film as an anti-sticking layer so as to prepare the self-adhesive polymer modified asphalt felt-free waterproof coil.

Self-adhesive polymer modified asphalt polyester waterproof coiled material (hereinafter referred to as PY type) is made of filament polyester felt as matrix, tackifying polymer modified asphalt as dip-coated material, and its upper surface is covered with polyethylene film and fine sand. The self-adhesive polymer modified asphalt polyester tire waterproof coiled material is prepared by taking shale, aluminum foil or isolation film as an isolation layer and coating a silicon isolation film on the lower surface as an anti-sticking layer.

Wide-width self-adhesive pre-paved polyester waterproof coiled material (hereinafter referred to as pre-applied PY-type) is a self-adhesive waterproof coiled material which is made of asphalt-based polyester waterproof coiled material as main material (add functional additives), coated with self-adhesive layer on both sides and attached with strippable silicon-coated film as isolating material.

The wide self-adhesive polymer pre-applied waterproof coiled material (hereinafter referred to as pre-applied P-type) is a high-polymer self-adhesive waterproof coiled material made of ethylene-vinyl acetate (EVA) and high-density polyethylene (HDPE) homogeneous sheet as the main material; the surface is coated with a “self-adhesive layer” and then covered with a silicon-coated isolating film. In accordance with engineering requirements, geotextiles can be compounded on the high-polymer layer to enhance the strength of coiled materials.

Wide-width wet-paving polyester waterproof coiled material is made of asphalt-based polyester waterproof coiled material as main material (adding functional additives), coated with self-adhesive layer on one side or on both sides, and attached with strippable silicon-coated film as isolating material.

Product features

Cold construction: No open fire, no adhesive, energy saving, environmental protection, low carbon and economy;

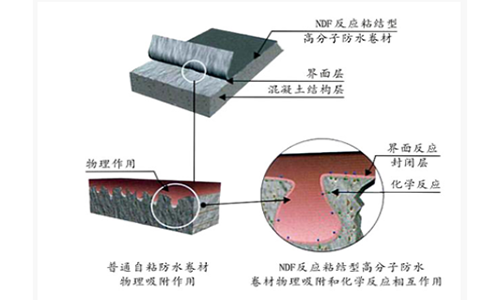

Excellent adhesion property: Excellent adhesion to the base layer, avoiding water channeling. The self-healing function, and the service life of the seam self-adhesion can be the same as that of the coiled material;

High tensile strength, high elongation, puncture resistance and corrosion resistance;

Excellent low temperature performance;

The construction loss of wide coiled material is less, and the construction is more convenient.

Scope of Application

Waterproof of non-exposed roof and underground works;

Waterproof of channel, swimming pool and other municipal works;

Waterproof of metro works with open excavation method;

It is especially suitable for waterproof works that cannot use open fire.

Excellent low temperature performance is more suitable for cold areas.

Waterproof protection of subway, cave depot, tunnel, basement, bridge, water conservancy dam, landfill, sewage treatment tank, planting roof and unmanned roofing.

Precautions for construction

It is strictly prohibited to lay coiled materials in rainy days, snowy days and strong winds of Grade V or above. When the construction temperature is lower than 5°C, the hot air gun shall be used for heating and bonding.

Safety education shall be provided to the personnel before construction. The safety protection facilities on the construction site shall be complete and the fire-fighting facilities shall be placed as required.

Packaging, storage and transportation

Packaging: Plastic bag rolling package

Storage and transportation: Products of different specifications and types shall be stacked separately and shall not be mixed. Avoid sun and rain, note the ventilation. The storage temperature shall not be higher than 45 °C. The stacking height shall not exceed five layers when the coiled materials are placed horizontally. The coiled materials shall be stacked in single layer when placed vertically. Avoid tilting and side pressure during transportation, and cover with tarpaulin if necessary.

Technical performance index

Self-adhesive polymer modified asphalt waterproof coiled material PY Implementation Standards GB 23441-2009

Serial No. |

Project |

I |

II |

||||

1 |

Soluble content g/m2 ≥ |

2.0 mm |

1300 |

- |

|||

3.0 mm |

2100 |

||||||

4.0 mm |

2900 |

||||||

2 |

Tensile property |

Tensile force N/50 mm ≥ |

2.0 mm |

350 |

- |

||

3.0 mm |

450 |

600 |

|||||

4.0 mm |

450 |

800 |

|||||

Elongation at maximum tension,% ≥ |

30 |

40 |

|||||

3 |

Heat resistance |

No sliding, flowing and dripping at 70 °C |

|||||

4 |

Low temperature flexibility°C |

-20 |

-30 |

||||

No cracks |

|||||||

5 |

Impermeability |

0.3 Mpa, water impermeability for 120 min |

|||||

6 |

Peel strength N/mm ≥ |

Coiled and rolled materials |

1.0 |

||||

Coiled material and aluminum board |

1.5 |

||||||

7 |

Water tightness of nail shank |

Passed |

|||||

8 |

Exudation, number of sheets ≤ |

2 |

|||||

9 |

Holding power min ≥ |

15 |

|||||

10 |

Thermal Aging |

Extension at maximum tensile force, % ≥ |

30 |

40 |

|||

Low temperature flexibility °C |

-18 |

-28 |

|||||

No cracks |

|||||||

Peel strength of coiled material and aluminum board N/mm ≥ |

1.5 |

||||||

Dimensional stability% ≤ |

1.5 |

1.0 |

|||||

11 |

Re-stripping strength of self-adhesive asphalt N/mm ≥ |

1.5 |

|||||